Home > Blog detail

Jul 2024

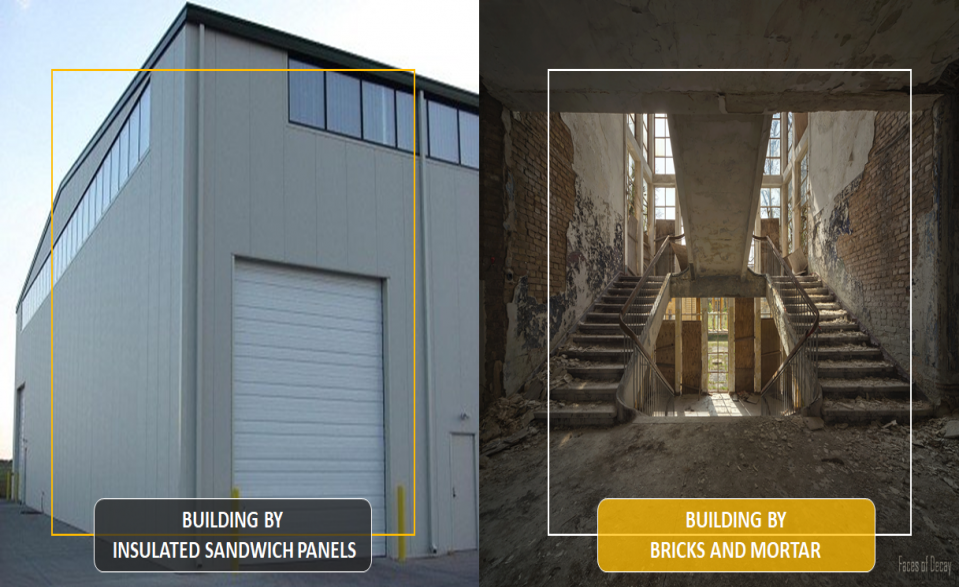

Bernie Sanders once said, “Every day we are paying more for energy than we should due to poor insulation, inefficient lights, appliances, and heating and cooling equipment- money we could save by investing in energy efficiency”. Now, answer a question. Whether India have in dearth of insulation technology? No, there are various kinds of Insulated sandwich panels in India namely PUF Panels, Rockwool Panels, Glasswool Panels, EPS Panels, and many more. It is the era of new-age technology and innovation with quick and easy alternatives to everything. The requirement of high-quality materials is a necessity in modern-day construction. Materials that are of high strength, lightweight, and durable are required for sustainable construction. In this modern era, the infrastructure and construction industry adopted new-age technology for construction, whether we talk about Warehouses, Factory Sheds, Shopping marts, Airports, Night Shelters, Schools, Hospitals, etc. Gone are the days when the infrastructure and construction industry used bricks and mortar for construction. All modern-day constructions are Pre-engineered construction. Insulated Sandwich panels are the future of Pre-engineered building construction which meets all the industrial and commercial requirements with its abundant advantages. Sandwich panel contain different insulations as a core like PUF, EPS, Rockwool, and Glasswool between two metal sheets. Insulated Sandwich panel have high insulation properties and have proven to be the most suitable alternative to brick-and-mortar construction. Insulated sandwich panels can be used for wall claddings as well as roofing. There are many other materials available in the market for wall claddings and roofing like asbestos sheets, aerocon panels, cement boards, single skin sheets, 3D panels, etc. Now, we will discuss how insulated sandwich panels are better in comparison to these available products in the market. Engko Engineering Company helps you in a very simple way to judge how insulated sandwich panel are the better choice for claddings by measuring some important parameters like construction time, finishing quality, health hazard, insulation properties, reusability, and cost. Construction Time: Cement-based sheets and panels are very high in weight and need a minimum of 4 manpower to install and lift one panel/sheet whereas Insulated sandwich panels are light in weight and can be easily installed with 2 manpower. On the other hand, we need to paint these cemented panels which further increases the construction time whereas insulated sandwich panel come with pre-painted GI sheets. So the overall construction time will reduced by more than 40% using insulated sandwich panels. Finishing Quality: If we talk about cement-based sheets and panels, the Jointing of two panels needs to be filled up with tape, silicon, and putty and after that we need to paint it which with time we will come to see cracks on that joint which looks very shabby than again we have to repeat the same process for its beautification whereas in insulated sandwich panels case we have tongue and groove joinery system which provides proper jointing and does not requires any tape, putty to cover the gap. These sandwich panels are ready to use once they are installed. Health Hazard: Generally cement-based sheets and panels use silica and asbestos content which is hazardous to health. Many research and reports state that silica is a cancer-causing agent, so occupants of these sheets are at huge risk. On the other hand, insulated sandwich panels have no such content even these sandwich panels are coming under the green product category. Insulation properties: There are no such insulation properties if we talk about single-skin sheets, cement-based sheets, and panels which are not at all good for providing ambient temperature for the people working and living inside the buildings. This also reduces the productivity by almost 70%. Insulated sandwich panel have more than 80% insulation properties as compared to other products available in the market. Normally, these insulated panels provide a difference of 6° ~ 8° from outside temperature without any air conditioning. These Sandwich panels are energy efficient too. Re-usability and Cost: Everybody in this world cares about the cost they are paying for the product in addition to their advantages. Initially, Insulated Sandwich panel are 20% more expensive as compared to cement board panels or aerocon panels, but when it comes to the execution stage we have to pay 5% ~ 7% extra for Cement board panels as a waste, labor costs as it is heavier in weight as compared to sandwich panels. Once after installation, we need to pay around 2% ~ 3% extra for its beautification and finishing in the case of cement board panels, on the other hand, insulated sandwich panels are ready to use. As insulated sandwich panel are energy efficient, they save almost 10% of electricity costs in the long run whereas no such cost can be availed by using other materials. There is no maintenance cost for sandwich panel but we need to invest a minimum of 10% for the maintenance of aerocon panels. The most fruitful advantage of sandwich panels is their re-usability, especially in cases of site infra where we can shift and use sandwich panels for a minimum of 5 times as in cement-based panels we will not be able to use its 70% for the 2nd time. So overall if we will see in the long run, Insulated sandwich panel are a minimum of 30% cheaper than the alternate products available in the market. In the end, we believe that insulated sandwich panel is the future of construction and hence we are dedicated to helping you achieve success by providing low-cost, sustainable, and highly appreciable insulated sandwich panels and other prefabricated structures!

Call

: +91-9667986005